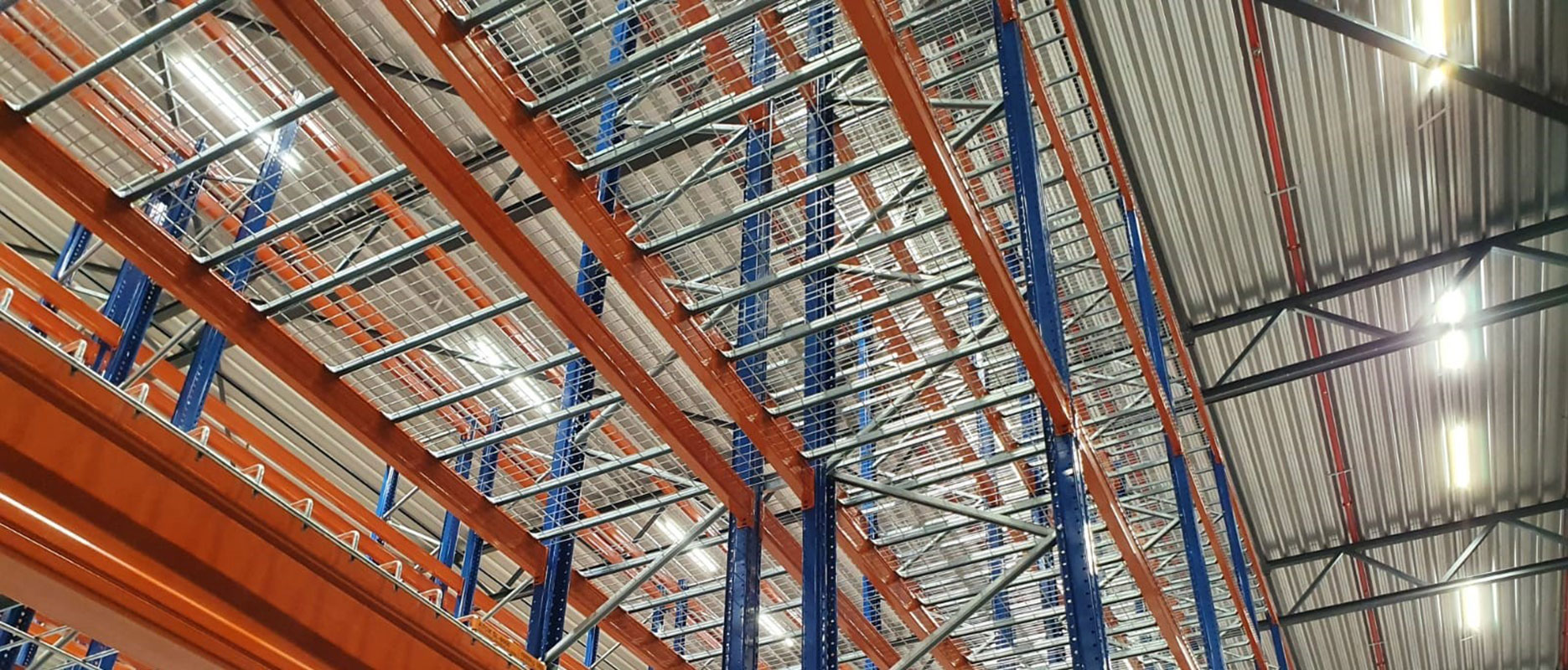

RACK MESH DECKS

META-C mesh decks are designed to adapt to any rack type shelf, to support pallet loading. They assure safety, preventing pallets from falling due to impacts or poor placement. CE marking.

RACK MESH

META-C mesh decks are designed to adapt to any rack type shelf, to support pallet loading. They assure safety, preventing pallets from falling due to impacts or poor placement and allow the customer to use various pallets of any size (even if they don’t rest on the stringers, like Düsseldorf pallets for example). They are supplied both Zinc-plated and Pre-Galvanised.

Product

- Designed to prevent the fall of pallets due to poor positioning, unintentional impacts by forklift operators, broken pallets or those in poor condition, even being able to support the pallet load without it resting on the beams.

- The design even enables the mesh decks to be folded upwards so that it holds back the pallet, stopping it from falling off the back of the shelf.

- With this mesh, Düsseldorf (800×600 mm) pallets can be placed without having to use slave pallets.

- It is also especially useful for irregular pallet batches, of any non-standard size and that can’t rest on the stringers, and useful for both heavy and light loads.

- For special loads, like Containers, it is tailor manufactured, reinforcing the area where their feet or skates are. Each case is studied to obtain the best solution and achieve an optimal, personalised design.

- Its versatile and easy assembly enables solutions to be devised quickly, without removing levels, without unloading shelves and making it possible to assemble by layer, gradually over time, according to need.

- It improves fire safety, as the water from the sprinklers passes through the mesh deck, to the levels below, helping to extinguish any fire.

Characteristics

- It improves fire safety, as the water from the sprinklers passes through the mesh deck, to the levels below, helping to extinguish any fire.

- It increases the forklift operator’s visibility when getting into position or picking up a pallet. It also improves the visibility of stock on the top levels and facilitates the passage of light towards the lower levels.

- While protecting the structure and staff, it increases safety and reduces insurance risk premiums.

- It favours a clean environment because dust doesn’t build up on the levels.